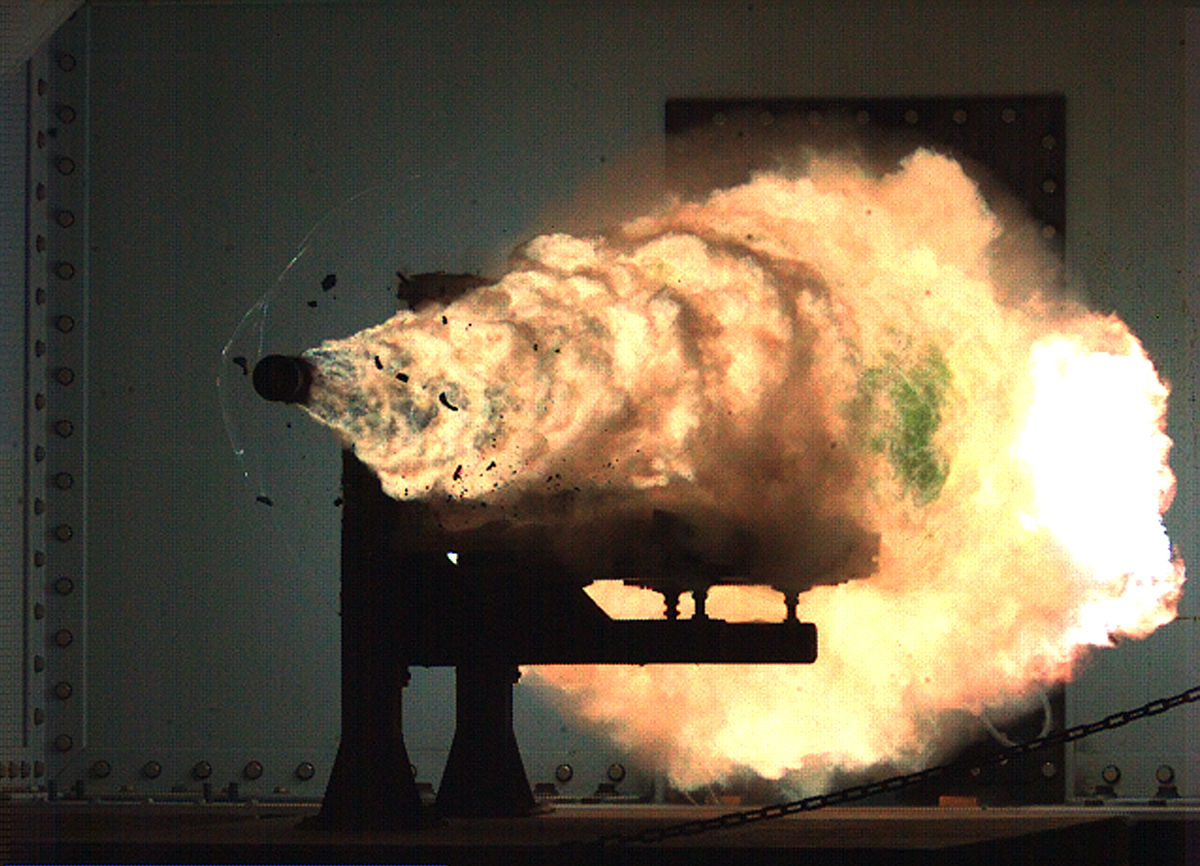

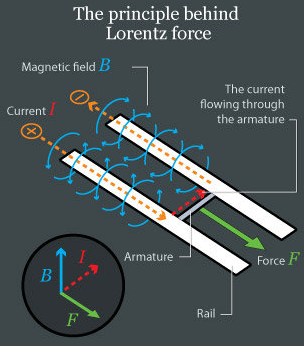

Guns are a technology that can be traced back to the 12th century in China. Since then, there have been numerous advances, with growing size and power, spherical bullets evolving into today's cone-like bullet, and barrels bored with twists to impart an angular momentum upon the bullet, just to name a few. However, all of these guns use explosives to create expanding gas in order to propel the projectile. Instead of using explosives, railguns use the electromagnetic force to propel a projectile.

By using the electromagnetic force, the gun no longer depends on the rate of gas expansion, and the limits thereof. Modern explosive-powered weapons can only reach a muzzle velocity of about 2 km/s, but railguns can easily reach more than 3 km/s. This speed also results in much superior range when compared to traditional weapons. Additionally, explosives do not have to be transported for use, making the railgun much safer for personnel.